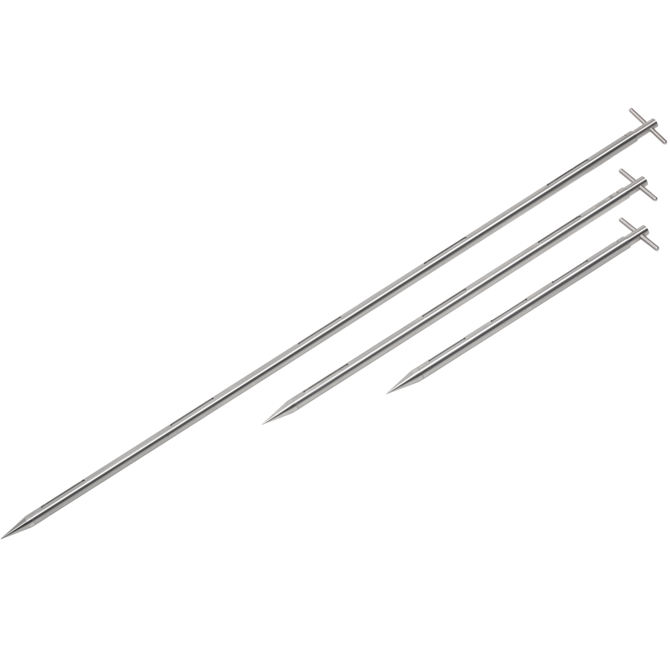

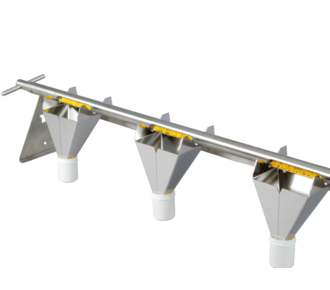

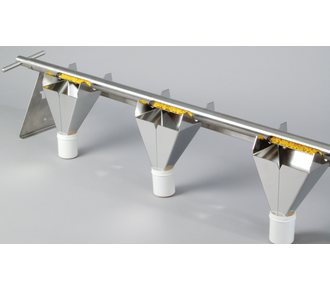

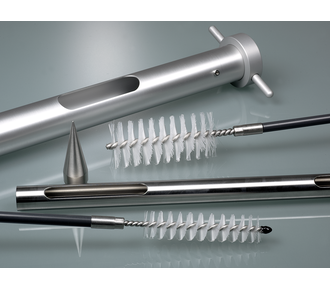

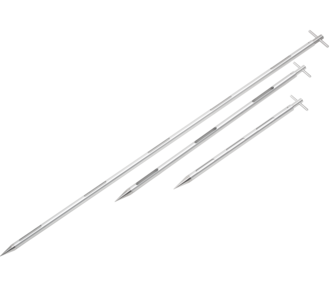

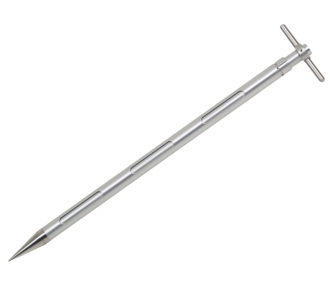

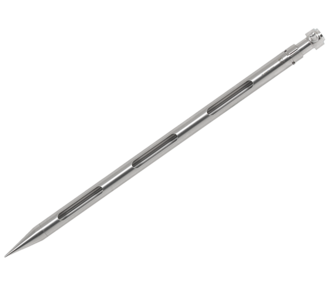

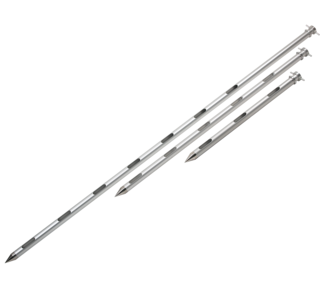

Multi-stage sampler multi-sampler 316L (1.4404)

Sampler for taking samples from several target points

- Taking multiple target point samples from different layers

- Enables targeted analysis or representative composite sample

- Versatile use, for a wide range of bulk materials

- Robust and durable thanks to high-quality workmanship

- Excellent chemical resistance

- Ideal for use in sensitive and aggressive areas

Packaging unit

Piece

Detailed information

The 316L (1.4404) stainless steel multi-sampler offers excellent chemical resistance and is resistant to a wide range of chemicals and cleaning agents.

The smooth surface of the stainless steel facilitates hygiene, cleaning and disinfection. The sampler is easily autoclaved and flame sterilised, minimising the risk of sample contamination.

Stainless steel is corrosion resistant, making it ideal for use in humid or aggressive environments such as those found in the food, pharmaceutical and chemical industries.

The sampler is extremely robust, even with intensive use or abrasive particles.

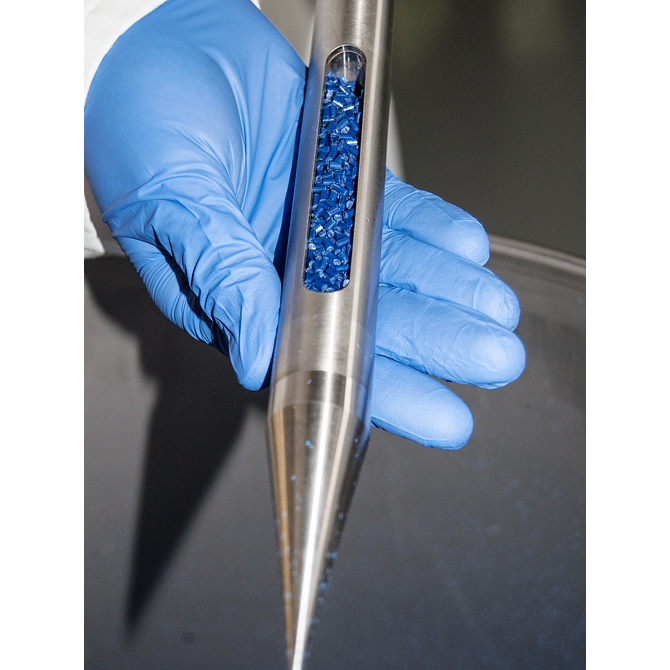

The multi-sampler with separate sampling chambers is a dedicated sampler for simultaneous sampling of multiple target points from different zones or layers of a wide variety of bulk solids.

The zone sampler allows differentiated and representative sampling from different depths or areas within a bag, drum, silo, big bag or heap. The multi-zone sampler is particularly useful in situations where the composition of the material varies with depth or across the surface and a single sample is not sufficient to accurately characterise the entire material.

The target point samples can be analysed individually after collection to investigate variability within a material or between different layers of material, or they can be subsequently mixed to produce a composite sample that is representative of the entire material. This method ensures that the final sample is representative, i.e. reflects the average composition of the material, which is essential for correct analysis and quality control.

The lances can be used both vertically and horizontally, making the sampler a very versatile sampler for different containers.

The design with minimal gap between the inner and outer tube reduces the risk of contamination and increases the accuracy of sampling. The removable tip also facilitates cleaning to effectively prevent cross-contamination between different samples.

Colour-coded caps facilitate identification and prevent confusion when using multiple samplers for different bulk solids.

The robust design of the multi-sampler ensures a long service life, even with regular use. The high quality workmanship ensures reliability and precision with every sample taken.

Typical application area of the product

The multi-sampler is used where it is necessary to take samples from several zones or layers simultaneously in order to obtain a comprehensive analysis of the composition, quality, impurities or inconsistencies of a material. For example, in the food industry to check the homogeneity and quality of bulk materials such as grain, corn, nuts, powders or granules; in the pharmaceutical industry for quality control of raw materials, intermediate and finished products; in the chemical industry to analyse chemicals, powders to ensure homogeneity of mixture and compliance with specifications; in the construction industry, materials science, research and development to test bulk materials such as sand, gravel and other materials.

How to use the product

- Turn the handle of the multi-collector clockwise, the multi-collector is now closed and can be pierced into the powder/granulate.

- At the desired depth, turn the handle of the collector counter-clockwise.

- This opens the collection chambers and fills them with sample.

- Turn the handle clockwise to close the collector and remove it from the powder/granulate.

- Open the multi-collector and empty the sample onto a suitable surface or use an emptying device (see accessories).

- Multi-stage sampler multi-sampler, 316L (1.4404)

- Colour coding caps

Specifications

General material

1.4404 (316L)

Stainless steel 1.4404, AISI 316L

Further materials

NBR

Nitrile butadiene rubber

Further materials

PTFE

Polytetrafluoroethylene

Lance dimensions

- Pipe Ø:

- 25 mm

- Outer Ø:

- 25 mm

- Plunge depth:

- 430 mm

- Total length:

- 580 mm

Sample chamber details

- Sample volume per chamber:

- 14 ml

- Number of collection openings:

- 3 itms

- Sample quantity:

- 42 ml

Collecting chamber dimensions

- Chamber length:

- 80 mm

- Start of the collecting chamber:

- 97 mm

- Chamber width:

- 12 mm

- Distance between the chambers:

- 56.5 mm

Sampling lances

- Sampling type:

- Multi point sampling

- Grain size samples:

- powdery/fine-grained,Medium-grained

- Sample material:

- free-flowing

- Special properties Sample lances:

- Removable tip,pointed tip,incl. colour coding

- Top:

- pointed

Complementary products

Closure seal close-it food & pharma 95x95

In response to many requests from our customers, we have developed close-it food & pharma, a closure seal with an adhesive approved for foodstuffs. The adhesive strength of the adhesive is almost the same as the original, the tried and tested close-it from Bürkle. close-it food & pharma also prevents bulk goods from trickling out after sampling.

The adhesive complies with European food directives. Like the original, close-it food & pharma has an aluminium foil barrier layer. This makes close-it food & pharma suitable for sampling foodstuffs, pharmaceuticals, cosmetics, food supplements, even frozen goods - in short, anywhere where special purity is required.

Emptying device

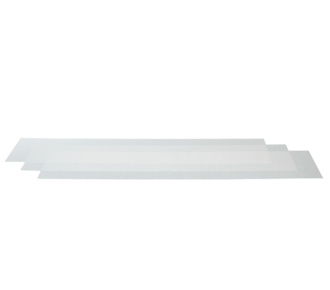

Quali-Paper for zone collectors

Sealing sleeves for zone samplers

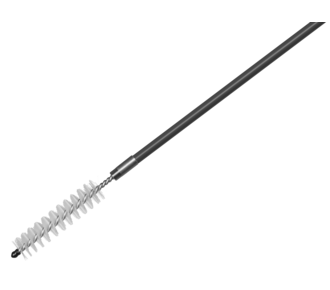

Cleaning brushes

Control seal close-it 95x95

Taking samples from sacks, boxes, bags, etc. with sampling lances is a common and time-proven practice. This produces holes through which easily flowing bulk goods could escape from the container. With the close-it seal, this can be prevented in an uncomplicated manner.

close-it has been especially developed for this purpose. The label has a sandwich-type structure (aluminium/paper) and seals the container hermetically (vapour barrier). This virtually prevents hygroscopic powders from clumping together.

The labels are available in different colours. With printing in red, blue, green, yellow, black or neutral (without printing in white).

close-it can be written on with ball-point pen, pencil or felt-tip marker.

The rear of the label is coated with a powerful adhesive. This means that close-it sticks firmly to most commercial containers, even to surfaces coated with fine powder, slightly moist or even frozen surfaces where conventional labels or adhesive tape will not stick.

Control seal close-it maxi 150x150

Taking samples from sacks, boxes, bags, etc. with sampling lances is a common and time-proven practice. This produces holes through which easily flowing bulk goods could escape from the container. With the close-it seal, this can be prevented in an uncomplicated manner.

close-it has been especially developed for this purpose. The label has a sandwich-type structure (aluminium/paper) and seals the container hermetically (vapour barrier). This virtually prevents hygroscopic powders from clumping together.

The labels are available in different colours. With printing in red, blue, green, yellow, black or neutral (without printing in white).

close-it can be written on with ball-point pen, pencil or felt-tip marker.

The rear of the label is coated with a powerful adhesive. This means that close-it sticks firmly to most commercial containers, even to surfaces coated with fine powder, slightly moist or even frozen surfaces where conventional labels or adhesive tape will not stick.

Closure seal close-it food & pharma Maxi 150x150

In response to many requests from our customers, we have developed close-it food & pharma, a closure seal with an adhesive approved for foodstuffs. The adhesive strength of the adhesive is almost the same as the original, the tried and tested close-it from Bürkle. close-it food & pharma also prevents bulk goods from trickling out after sampling.

The adhesive complies with European food directives. Like the original, close-it food & pharma has an aluminium foil barrier layer. This makes close-it food & pharma suitable for sampling foodstuffs, pharmaceuticals, cosmetics, food supplements, even frozen goods - in short, anywhere where special purity is required.

close-it tape Special adhesive tape

Besides the individually detachable close-it and close-it food & pharma closure labels, our repeatedly tested and proven control seal is now also available on a continuous roller. This helps you discover whether you require only a small piece, for example for closing a small hole, or for marking a specific point. Or whether you want to repair a long crack or a large hole quickly, reliably and easily. With its extremely strong adhesive strength, close-it tape holds on the most diverse bases, where the glue effect of normal adhesive tape quickly reaches its maximum capacity.

For universal use, we have kept the adhesive tape close-it tape in white with tear-off lines. It can be labelled with permanent ink and locks gas-proof. Available in the classic close-it design, as well as close-it tape food & pharma, with a food-compatible adhesive.

close-it tape food & pharma

Besides the individually detachable close-it and close-it food & pharma closure labels, our repeatedly tested and proven control seal is now also available on a continuous roller. This helps you discover whether you require only a small piece, for example for closing a small hole, or for marking a specific point. Or whether you want to repair a long crack or a large hole quickly, reliably and easily. With its extremely strong adhesive strength, close-it tape holds on the most diverse bases, where the glue effect of normal adhesive tape quickly reaches its maximum capacity.

For universal use, we have kept the adhesive tape close-it tape in white with tear-off lines. It can be labelled with permanent ink and locks gas-proof. Available in the classic close-it design, as well as close-it tape food & pharma, with a food-compatible adhesive.

Similar products

Multi-stage sampler multi-sampler 316L (1.4404)/PTFE

Multi-stage sampler multi-sampler, aluminium

Spiralus zone collector

Aluminium all-layer sampler

All-layer sampler 316L (1.4404)

Uno sampler target point collector

Jumbo sampler zone sampler for larger volumes, Multi

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

polski

polski

português

português

Türkçe

Türkçe

中文

中文