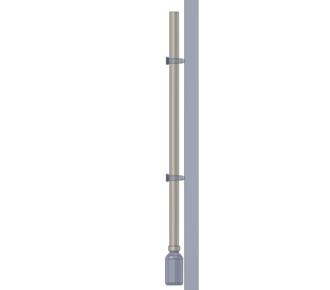

Barrel pump stainless steel - discharge elbow

Drum pump for precise dispensing of flammable liquids

- Ideal for highly flammable or aggressive liquids

- Meets the highest safety standards

- Economical and durable

- For precise and safe filling

Packaging unit

Piece

Please note

Caution! When handling flammable, highly flammable liquids, the explosion protection guidelines must be observed. All parts must be earthed, use anti-static set!

The pump is not suitable for acetone or similar drying solvents.

Detailed information

This stainless steel barrel pump has a fixed discharge elbow for accurate and safe filling of liquids. The robust stainless steel discharge elbow directs the liquid in a targeted and controlled manner, preventing spillage and splashing.

For use in demanding environments, the stainless steel barrel pump with discharge elbow is extra durable and easy to clean.

Stainless steel drum pumps are powerful and versatile piston pumps for transferring flammable or aggressive liquids and chemicals.

Their electrical conductivity makes the drum pumps ideal for highly flammable or combustible liquids. They have been specially developed for use in zones 0 and 1 (explosion groups II A and II B) and are DEKRA-tested. When used for flammable media, the pumps must be grounded.

The PTFE seals not only guarantee high chemical resistance, but also excellent sliding properties during the pumping process.

Stainless steel drum pumps are very flexible and versatile. They are ideally suited for a wide variety of drums, containers or other receptacles (approx. 60 to 1000 l capacity, up to 91 cm depth) and are thus true all-rounders in the workshop or production.

Compared to conventional solvent pumps for highly flammable liquids, our stainless steel drum pumps offer excellent value for money.

The durable and robust drum pumps made of high-quality, corrosion-resistant stainless steel (1.4301) guarantee a long service life, especially in humid or aggressive environments.

Typical application area of the product

Stainless steel drum pumps are electrically conductive and resistant to a wide range of chemicals, enabling safe and efficient transfer or metering of liquids in the chemical, pharmaceutical or food industries.

How to use the product

- Screw on the discharge elbow.

- Insert the barrel pump with barrel screw fitting (accessory) into the barrel and screw in hand-tight.

- If necessary, adjust the height of the riser tube.

- Place the filling container under the discharge bend.

- Pull the cap off the discharge bend.

- Operate the piston rod with the handle and fill the liquid.

- During the last pump stroke, push the piston rod into the pump as far as it will go.

- Carefully unscrew the pump from the barrel.

- Rinse the barrel pump with pH-neutral liquid.

- Stainless steel barrel pump

- Discharge elbow

Specifications

General material

1.4301 (AISI 304)

Stainless steel (1.4301), AISI 304

Further materials

PTFE

Polytetrafluoroethylene

Throughput

- Conveying capacity:

- 190 ml/stroke

- Delivery rate min.:

- 9 l/min

- Max. delivery rate:

- 22 l/min

Ø

- Immersion tube Ø:

- 32 mm

Pump outlet

- Outer outlet Ø:

- 12 mm

- Length of discharge tube:

- 290 mm

- Outlet type:

- Discharge tube

Delivery tube

- Immersion depth max.:

- 36 cm

Limit values

- Viscosity up to:

- 500 mPa·s

Colouring

- Colour:

- silver

Connection

- For openings from:

- 32 mm

- Connection type:

- Barrel screw joint

Filling container

- Adjusting the immersion depth:

- Immersion depth infinitely adjustable

- For containers up to:

- approx. 30 litres

How to fill

- Drive type:

- manually operated

- Pump type:

- Reciprocating piston pump

- Special features Pumps:

- Exchangeable outlet elbow/hose

You need

A variety of barrel fittings and threaded adapters, ensure the pump fits your application.

The discharge hose and discharge elbow are unscrewable and interchangeable.

Note that an anti-static kit is required if the pump is used for flammable media.

Complementary products

Brass barrel screw joint

Barrel screw joint made of nickel-plated brass for barrel pump stainless steel. Prevents electro-static charge in combination with the Anti-static set. For the safe transfer of flammable and easily flammable liquids. For containers with R 2" steel fine thread inside.

The container connectors make decanting even easier and safer with their more secure connection to barrels.

Discharge hose 1.2 m with stopcock

The 1.2-meter-long discharge hose with spigot is a practical accessory for drum and canister pumps. It consists of a flexible hose and an integrated shut-off valve (spigot) at the end. The valve allows precise control of the liquid flow and can be completely closed if needed — enabling drip-free dispensing. The hose itself is made of high-quality, chemically resistant material (PVC or stainless steel), making it suitable for a wide range of liquids, including oils, solvents, or water. With a length of 1.2 meters, it offers ample flexibility to conveniently fill containers even at a slight distance.

Gastight barrel connector

The gas tight barrel screw joint prevents hazardous gases from escaping from the barrel. G2" steel barrel thread, non-return valve with connection 1/8". Nickel-plated brass, seals made of FKM.

The container connectors make decanting even easier and safer with their more secure connection to barrels.

Universal thread adapter

Universal thread adapter for nearly all drums and other containers with opening of 48–75 mm in diameter, regardless of the respective thread. The thread adapter can be mounted quickly and easily with clamping screws and can be used for different container openings.

With G2" connector thread for Bürkle drum screw connections and pumps with immersion tube diameter up to 32 mm.

Drain safety stand

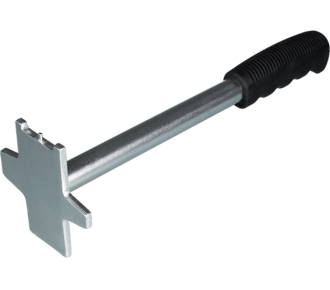

Universal drum wrench

Drum holder

Similar products

Stainless steel barrel pump - discharge hose & valve

Solvent pump hand operated

Hand-operated solvent pump for contaminationfree removal of organic solvents and flavouring agents. The hand pump works according to the overpressure principle. An excess pressure is built up in the tank with the pump ball, forcing the liquid out of the container.

Pouring flammable liquids

All medium-contacting parts are made of stainless steel AISI 304 (1.4301) and PTFE. The Bürkle anti-static set can be used to ground the pump for dispensing flammable liquids so that no electrostatic charge forms.

Gastight version

The pump can be completely closed off with the two ball valves so that no dangerous vapours can escape after dispensing.

Suitable for different containers

The hand pump is suitable for containers up to 60 litres.

Solvent pump hand operated, for tin-foil canisters

The solvent pump for tinplate canisters with pull-out spout puts an end to the risky decanting of dangerous substances into another container. The included thread adapter fits to the standard pull-out spouts - immediate safety!

Solvent pump foot operated - discharge tube

Barrel pump for solvents with rigid discharge tube.

Solvent pump foot operated - discharge hose/stopcock

Barrel pump for solvents with discharge hose and stopcock made of stainless steel/PTFE.

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

polski

polski

português

português

Türkçe

Türkçe

中文

中文