Take samples - but do it right

Flawless sampling

When taking samples, a random test is taken from an overall quantity. These samples serve as the basis for the analysis regarding quality assurance. The correct procedure for taking spot samples is therefore a very important subject. Only with representative and authentic samples can reliable information about the quality, properties or composition of a particular material be provided.

Taking samples

Very precise material analyses can be carried out with the most up-to-date technology. However, the technology is no good if an error occurs when the sample is taken and this error continues through all phases of the analysis, with the consequence that the final result of the quality check is wrong.

Correct information about the properties of a material can only be provided if the sample is taken properly and treated in the same way as in the subsequent analysis. The basic point is that the properties and composition of the sample quantity correspond exactly with the material quantity that has to be evaluated.

When taking samples, some essential stipulations such as DIN-standards have to be complied with. The recommendation is to follow a company-internal checklist which should be a fixed component of a company's quality standards. All relevant steps for taking samples are documented in this checklist so that they can be traced at any time.

Taking samples - but how?

Location for taking samples

The location from where the samples are taken has to be as clean as possible. At the very least, the use of clean samplers, equipment and tools has to be considered. During the procedure, no external factors must influence the sampling. Even small external contamination can significantly alter the examination result. Detergents which are used to clean the samplers or the sample packaging can also falsify the result of the analysis.

Taking samples - but who?

Specialist personnel

Only skilled personnel should take the samples. It must be guaranteed that sampling is carried out exactly in accordance with the stipulated DIN-standards or internal guidelines.

Technical knowledge is of utmost importance because altered circumstances can only be reacted to on-site. Only trained personnel can quickly and safely recognise mistakes that occur or altered circumstances and react accordingly.

Taking samples - with what?

Sampling equipment

Choosing the right sampling equipment depends on many different selection criteria. It depends on the material properties of the sampler as well as on the type of sampling, the container or the site where the material is located, and the frequency with which the sampling has to be carried out. In addition to individual requirements for sampling, all equipment should fulfil the basic principles explained below:

Sampler material

The equipment should be made of inert substances from which no material can come loose and which does not react with other substances and therefore cannot contaminate the sample. The inert substance depends on the medium to be sampled. As a general rule, samplers made of stainless steel and high-quality plastic such as PTFE are very suitable.

Cleaning the sampling equipment

It should be easy and quick to clean the equipment and – under certain conditions – to sterilise it. In the food industry, sterile-packed disposable samplers are recommended which can be disposed of after use.

Processing the samplers

Samplers must not have any grooves or crevices because residual material collects in such crevices and cannot be easily removed. This means that cross-contamination and memory effects can no longer be ruled out.

Surface of the equipment

The samplers' surfaces have to be especially smooth, for example, electro-polished stainless steel or PTFE. This prevents material from being deposited and simplifies cleaning. When selecting the appropriate sampling equipment, you must ensure that it is finished properly on the inside. Equipment with only a smooth external surface will not meet any quality standards.

Sampling techniques – physical and analytical sampling

A distinction is made between physical and analytical/chemical sampling.

During physical sampling, the bulk density, material distribution, material properties and – if required – colouring or contamination are determined. It is especially important in this case that the sampler does not change or destroy the material's properties while taking the sample. A sample taken onsite still has to be transported. During packing and transport, the same high quality standards should apply as during sampling, so that the sample reaches the laboratory unaltered.

During analytical sampling, special attention must be paid to cleanliness in addition to the aspects listed above. However, the material properties can be disregarded at times because the sample will be specially processed. In this case, equipment can be used which changes the physical properties of the material.

Sampling techniques

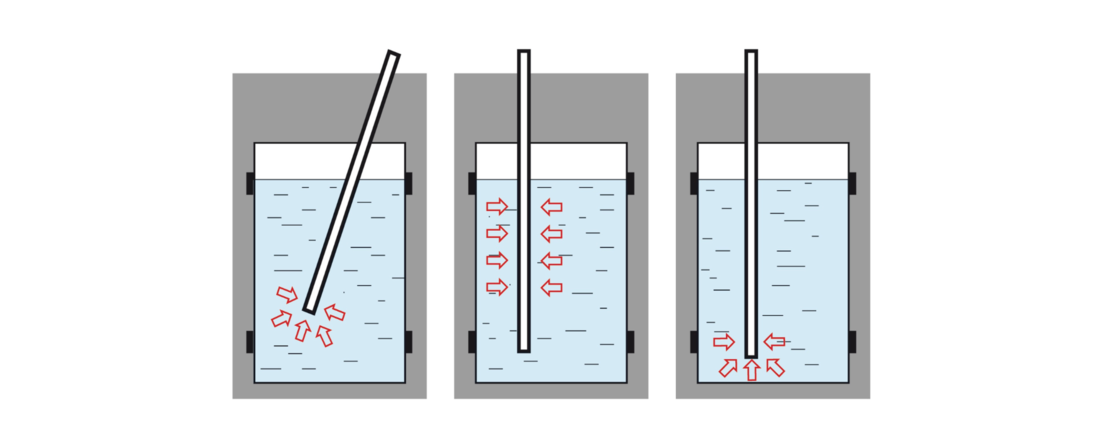

Cross-sectional sampling

A sample is taken through all material layers to provide a representative cross-section.

Point sampling

A targeted sample is taken from a pre-determined point. This is done to determine the condition of the material precisely at this point, or several point samples are taken over a larger area or in a large volume container to get an authentic cross-section. All point samples together therefore provide a representative cross-section.

Completing the sampling procedure

After the sample has been taken, it must be packed for transport. Clean sampling containers connected directly to the sampling equipment are ideal. The sample has no contact with the environment and is packed for transport at the same time. The same conditions that relate to the sampling equipment also apply to packaging, storage, and transport of a sample. Here, too, you must pay attention to the cleanliness of the packaging material and the risk of contamination from loose substances. The sample container is then labelled so that no mix-up can occur and taken to the laboratory – if necessary in coolers. Coolers with temperature monitors in which the ideal cooling temperature is maintained, are recommended.

Sample container, round

Sample box with screw lid. Ideal for taking samples and transport. Emptying without residues because there are no crevices.

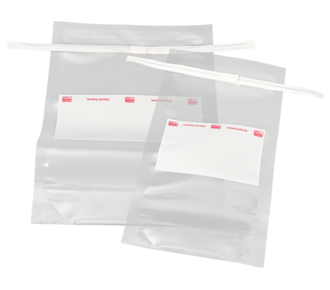

Sampling bag SteriBag

The bags are made of polyethylene and are therefore exceptionally tearproof and leakproof.

The SteriBag sampling bag is distinguished by its safe handling. When used according to instructions, samples are guaranteed sterile.

Integrated safety: The tab-ends are sealed in plastic film to prevent skin injuries.

Sampling bag SteriBag with labelling area

The bags are made of polyethylene and are therefore exceptionally tearproof and leakproof.

The SteriBag sampling bag is distinguished by its safe handling. When used according to instructions, samples are guaranteed sterile.

Integrated safety: The tab-ends are sealed in plastic film to prevent skin injuries.

SteriBag StandUp sample bag

SteriBag StandUp is a sterile sample bag with a stand-up base. The special bottom unfolds as soon as the bag is filled. This makes SteriBag StandUp stable and able to stand on its own without a separate stand or support, leaving both your hands free to take the sample and fill the bag. The wire bracket at the closure keeps the bag open, making it easy and convenient to fill.

Can be used for samples available as liquids, powders, solids and pastes; suitable for foods and can be frozen.

The stable standing SteriBag StandUp sample bag is easy and safe to transport.

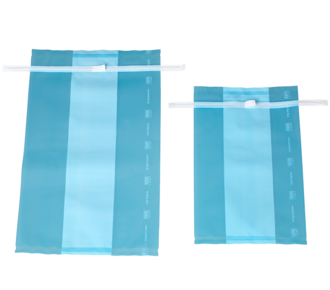

Sampling bag SteriBag Blue

The sterile sampling bag SteriBag Blue is especially well suited for use in the food, animal feed and pharmaceutical industries. To prevent the danger of foreign matter in production, the sample bags and the tear-off closure are coloured blue. This shade of blue does not occur in a natural form in foodstuffs. Because of this it is highly visible and can be reliably discovered in a visual check if a bag or parts of it are ever mixed into production.

Thanks to the large opening, the SteriBag Blue can be filled easily. The sample bag with labelling field is space-saving, easy to transport and leak-proof.

Sampling bag SteriBag Cleanroom

The sampling bag SteriBag Cleanroom with double packaging can be placed directly in the clean room. 25 sample bags are placed in double secondary packaging. They can be removed one after the other and are therefore ideally suited for introducing into the clean room. Then the sterile bags can be used directly in the clean room.

The disposable sample bag has a labelling field, saves space and is also easy to transport. The large bag opening makes it easy to pour in the sample.

SteriBag Premium tamper-proof sample bag

The SteriBag Premium sample bags uniquely combine a high degree of security, sterility, tamper evident closure and traceability, they are used to securely transport and for the storage of samples.

After sampling, the sample can be filled directly into the sterile sample bag. The tamper-evident closure seals the bag liquid-tight and secure. When trying to open the closure again, the word "STOP" appears clearly visible. Both the sample bag and the tear-off field are labeled with a unique tracking number, this allows a complete documentation and traceability.

SteriPlast® Kit – sterile sampling set with spatula

The sampling set SteriPlast® Kit consists of ten sample spatulas and ten SteriBag Premium tamper-proof sample bags.

The scoops or spatulas are clean room manufactured and individually packed. The sample bag SteriBag Premium has an integrated sealing and is liquid-tight. A unique tracking code on both the bag and the tear-off field guarantees complete documentation and traceability.

SteriPlast® Kit including scoop 50 ml and SteriBag Premium 300 ml.

Advice

If samples are taken from sacks or bags, the insertion points must be closed again afterwards. For this, special labels should be used that stick firmly to dirty surfaces and can be written on.

Control Seals close-it

Control seal close-it 95x95

Taking samples from sacks, boxes, bags, etc. with sampling lances is a common and time-proven practice. This produces holes through which easily flowing bulk goods could escape from the container. With the close-it seal, this can be prevented in an uncomplicated manner.

close-it has been especially developed for this purpose. The label has a sandwich-type structure (aluminium/paper) and seals the container hermetically (vapour barrier). This virtually prevents hygroscopic powders from clumping together.

The labels are available in different colours. With printing in red, blue, green, yellow, black or neutral (without printing in white).

close-it can be written on with ball-point pen, pencil or felt-tip marker.

The rear of the label is coated with a powerful adhesive. This means that close-it sticks firmly to most commercial containers, even to surfaces coated with fine powder, slightly moist or even frozen surfaces where conventional labels or adhesive tape will not stick.

Control seal close-it maxi 150x150

Taking samples from sacks, boxes, bags, etc. with sampling lances is a common and time-proven practice. This produces holes through which easily flowing bulk goods could escape from the container. With the close-it seal, this can be prevented in an uncomplicated manner.

close-it has been especially developed for this purpose. The label has a sandwich-type structure (aluminium/paper) and seals the container hermetically (vapour barrier). This virtually prevents hygroscopic powders from clumping together.

The labels are available in different colours. With printing in red, blue, green, yellow, black or neutral (without printing in white).

close-it can be written on with ball-point pen, pencil or felt-tip marker.

The rear of the label is coated with a powerful adhesive. This means that close-it sticks firmly to most commercial containers, even to surfaces coated with fine powder, slightly moist or even frozen surfaces where conventional labels or adhesive tape will not stick.

Closure seal close-it food & pharma 95x95

In response to many requests from our customers, we have developed close-it food & pharma, a closure seal with an adhesive approved for foodstuffs. The adhesive strength of the adhesive is almost the same as the original, the tried and tested close-it from Bürkle. close-it food & pharma also prevents bulk goods from trickling out after sampling.

The adhesive complies with European food directives. Like the original, close-it food & pharma has an aluminium foil barrier layer. This makes close-it food & pharma suitable for sampling foodstuffs, pharmaceuticals, cosmetics, food supplements, even frozen goods - in short, anywhere where special purity is required.

Closure seal close-it food & pharma Maxi 150x150

In response to many requests from our customers, we have developed close-it food & pharma, a closure seal with an adhesive approved for foodstuffs. The adhesive strength of the adhesive is almost the same as the original, the tried and tested close-it from Bürkle. close-it food & pharma also prevents bulk goods from trickling out after sampling.

The adhesive complies with European food directives. Like the original, close-it food & pharma has an aluminium foil barrier layer. This makes close-it food & pharma suitable for sampling foodstuffs, pharmaceuticals, cosmetics, food supplements, even frozen goods - in short, anywhere where special purity is required.

seal-it security seal

Retention samples are kept to provide a sample for comparison at a later date. The unambiguous proof that the retention sample is identical to the original sample is only possible with clearly marked and sealed containers. However, sealing is frequently not possible unless eyelets are present.

seal-it provides the solution! The seal-it self-adhesive label sticks to all conventional containers. Thanks to its unbelievable adhesive power it cannot be removed.

If a container opening is closed with seal-it, then the container cannot be opened without destroying the seal-it label. seal-it is additionally provided with several cross-perforations which immediately tear when manipulated like a motorcar tax disc.

seal-it can be used to securely seal bottles, sample bags, sacks, specimen bags, envelopes, etc. – in principle any type of container. The aluminium foil adapts seal-it to any container shape. The white labelling field on seal-it can be written on with all conventional writing tools with, for example, contents information, sampling date, name of operator, etc.

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

português (Brasil)

português (Brasil)

Türkçe

Türkçe

中文

中文

한국어

한국어