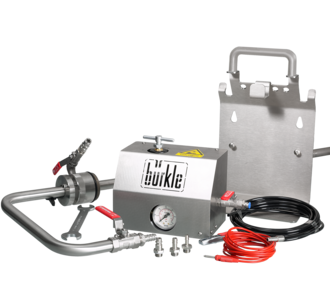

Withdrawal system for solvents with discharge hose

Compressed air-driven solvent pump with flexible hose

- Safe filling of large quantities of solvent

- Flexible connection options thanks to a variety of adapters

- Operation with compressed air or inert gas (e.g. nitrogen), suitable for a wide range of media

- Outlet hose enables flexibility during filling

bk.product.packaging-unit.label

Piece

bk.product.warnings.headline

Caution! When handling flammable, highly flammable liquids, the explosion protection guidelines must be observed. All parts must be earthed, use anti-static set!

The tank, pump and pressure regulating unit must be earthed! Use antistatic set in addition for pump!

Detailed information

With the dispensing system for solvents with discharge hose, the drum pump is equipped with a flexible discharge hose. The hose enables safe and precisely dosed transfer of the solvent to be filled, even into containers that are further away.

The dispensing system for solvents is used to safely transfer solvents from larger containers such as drums or canisters into smaller containers or directly to the point of use. With the dispensing system for solvents, high-purity liquids can be filled quickly and easily.

Using the solvent dispensing system minimizes health hazards from solvent vapours and reduces the risk of spills, which can lead to environmental damage or hazardous situations in the workplace.

Filling is simple: pressurized gas (compressed air or nitrogen) is used to create an overpressure in the container, which forces the liquid out of the container. The advantage of operating with pressurized gas is that the user can easily remove larger quantities and has both hands free to fill the solvent. This means that even hazardous media such as acetone, ethanol, methanol etc. can be filled safely and dosed precisely via the drain cock. For oxygen-sensitive or high-purity media, operation with inert gas (e.g. nitrogen) is possible.

The drum screw connection (G 2") and the stopcocks hermetically seal the drum and pump. This means that no solvent-containing vapors can escape after filling - protecting the health of the user and the environment.

The transportable dispensing system enables flexible working.

It consists of a drum pump and a suspended pressure control unit that adjusts the inlet pressure and provides additional safety against incorrect operation. A pressure gauge enables visual control of the inlet pressure.

The pump can be easily attached to the container using a drum screw connection.The connection to compressed air or nitrogen (3-10 bar) can be made via a mobile or stationary compressed air supply.

bk.product.scope_of_application.tab_headline

The dispensing systems for solvents can be used for UN containers and drums with a test pressure of at least 150 kPa.

They enable safe and accurate filling of various solvents, especially in laboratories, in the chemical industry and wherever large quantities of solvents are handled. The system makes a significant contribution to occupational safety by reducing the risk of fires, explosions, damage to health through inhalation of vapors and environmental damage caused by improper handling of hazardous liquids.

bk.product.utilization.tab_headline

- Insert the pump into the container, screw in the barrel screw connection hand-tight and airtight.

- Screw the outlet hose onto the riser pipe.

- Remove the protective plugs from the IN inlet and OUT outlet.

- Fit the compressed air supply inlet hose with G 1/4" thread or suitable adapter.

- Lightly tighten the adapter with a wrench.

- Open the regulating valve of the pressure control unit until the pressure gauge indicates a pressure between 0.2 and 0.3 bar.

- Connect the connecting hose to the OUT outlet of the pressure regulator unit.

- Connect the connecting hose to the quick coupling of the pump.

- Open the stopcock of the pump and open the stopcock of the pressure regulator unit to generate overpressure.

- Hold the outlet hose in the filling container, open the outlet hose stopcock and remove the liquid.

- After filling, close the stopcock on the outlet hose.

Material

- Solvent pump with discharge hose

- Pressure control unit

- Transport stand

- 2x protective plugs

- Earthing cable for pressure control unit

- Connecting hose

- Key for pressure supply

- 3x pressure supply adapter (G 1/4"): 1x coupling plug NW 7.2 mm, 1x hose nozzle for inner Ø 6 mm, 1x hose nozzle for inner Ø 8 mm

bk.product.specifications.title

bk.product.general_material.label

1.4301 (AISI 304)

Stainless steel (1.4301), AISI 304

bk.product.detail_material.label

PTFE

Polytetrafluoroethylene

Connection

- Anschlussart:

- Barrel screw joint

- Gewinde:

- G 2 inch

- Gewindeausführung:

- External thread

Throughput

- Förderleistung ca.:

- 10 l/min

Limit values

- Viskosität bis ca.:

- 500 mPa·s

Ø

- Tauchrohr-Ø:

- 21.3 mm

Pump outlet

- Auslauf-Ø außen:

- 13 mm

- Länge Auslaufschlauch:

- 1.2 m

- Auslauftyp:

- Discharge hose

Delivery tube

- Eintauchtiefe:

- 95 cm

Filling container

- Eintauchtiefe justieren:

- Immersion depth infinitely adjustable

- Für Behälter bis:

- approx. 220 liters

How to fill

- Antriebsart:

- Compressed air operated

- Pumpentyp:

- Overpressure pump

- Besondere Eigenschaften Pumpen:

- Exchangeable outlet elbow/hose,incl. transport stand,incl. grounding cable

bk.product.mandatory_accessories.title

Numerous thread adapters enable adaptation to all commercially available containers.

bk.product.similar_products.tab_title

Dispensing system for solvents with discharge elbow

Solvent pump foot operated - discharge hose/stopcock

Barrel pump for solvents with discharge hose and stopcock made of stainless steel/PTFE.

Solvent pump foot operated - discharge tube

Barrel pump for solvents with rigid discharge tube.

Solvent pump hand operated

Hand-operated solvent pump for contaminationfree removal of organic solvents and flavouring agents. The hand pump works according to the overpressure principle. An excess pressure is built up in the tank with the pump ball, forcing the liquid out of the container.

Pouring flammable liquids

All medium-contacting parts are made of stainless steel AISI 304 (1.4301) and PTFE. The Bürkle anti-static set can be used to ground the pump for dispensing flammable liquids so that no electrostatic charge forms.

Gastight version

The pump can be completely closed off with the two ball valves so that no dangerous vapours can escape after dispensing.

Suitable for different containers

The hand pump is suitable for containers up to 60 litres.

Solvent pump hand operated, for tin-foil canisters

The solvent pump for tinplate canisters with pull-out spout puts an end to the risky decanting of dangerous substances into another container. The included thread adapter fits to the standard pull-out spouts - immediate safety!

Deutsch

Deutsch

English

English

français

français

español

español

русский

русский

italiano

italiano

Türkçe

Türkçe

中文

中文