What is gamma ray sterilisation?

Our SteriPlast® products are sterilised by gamma rays, i.e. all micro-organisms contained within or adhering are killed off. But what exactly are gamma rays and how do they bring about a sterilisation of Bürkle products?

What are gamma rays and how do they have an effect?

Gamma rays are electromagnetic waves (such as light, infra-red or UV rays). However gamma rays have a shorter wavelength and therefore have more energy.

During irradiation, this energy is transferred to the electrons of the molecules of the products and in the process generates highly reactive radicals. This is why we speak of ionising radiation. These free radicals now break up the DNA of the existing micro-organisms so that they can no longer multiply and are killed off. The radiated product is therefore sterile.

As the gamma rays only affect the electron shell of the molecule, it is physically impossible for the radiated product to be radioactive itself.

The absorbed energy during radiation is measured in Kilograys (kGy). This absorbed energy depends on different factors (including exposure period, dosing of radiation, density of the material, package size) and is checked using a dosimeter. In this way it is ensured that each product receives the specified radiation dose.

How does the irradiation process take place?

The irradiation process takes place in a special system. The gamma rays required for this arise as a result of the decay of the radioactive isotope cobalt 60. This is stored in stainless steel cylinders within the system and represents the radiation source. During the radiation operation, the radiation source of the products to be irradiated go round on a conveyor system.

To be able to access the system without danger, the radiation source can be lowered in a water tank whose water column shields the rays.

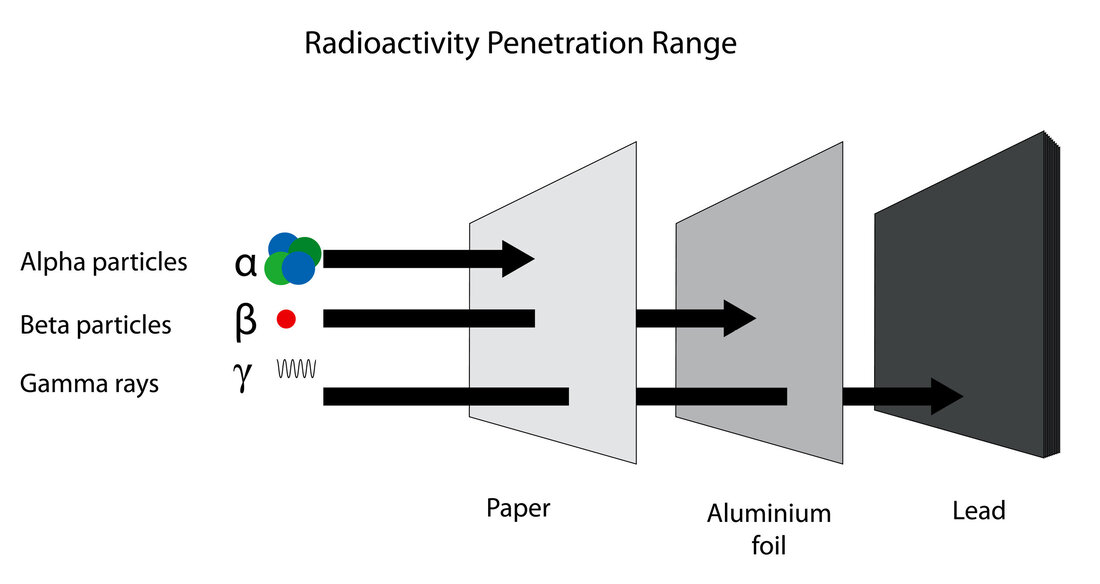

A big advantage is the good penetrating capacity of the gamma rays that allow the products in the final packaging to be sterilised. This simplifies the production process and ensures that the products cannot be re-contaminated by subsequent packaging work.

Advantages of gamma ray sterilisation

- Reliable and effective procedure for sterilisation

- Flexible and diverse applications

- Good penetrating capacity enables radiation in the packaging

- Process is gentle on the product as no temperature increase is necessary

- No chemical residues or toxic substances on the product

- Products can be used immediately after radiation

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

português (Brasil)

português (Brasil)

Türkçe

Türkçe

中文

中文

한국어

한국어