Packaging containers with UN approval

What is a container with UN approval?

The person who fills a package with hazardous materials is responsible for its safety on dispatch. In a UN approved container you can transport hazardous goods safely without having to repack them and thus save costs.

What is “UN-approved”?

The UN has drawn up a list of more than 6000 hazardous substances classified according to the risk that they represent; this determines their packaging group.

Packaging group I (X) corresponds to a high degree of risk represented by the contents, e.g. very corrosive substances; packaging group II (Y) a medium degree of risk and packaging group III (Z) less hazardous substances.

The UN approval describes the type of packaging to be used for the transport of hazardous substances. The certificate is issued by recognized material testing institutes. In mass production the manufacturer must guarantee that the product meets the specifications for the type of packaging and that the packaging is manufactured and tested according to a quality assurance program recognized and monitored by the registration office.

Test criteria

(limits must not be infringed)

- chemical compatibility

- temperature

- flash point < 61 °C

- drop height

- pressure (i.e. vapor pressure of the contents plus partial pressure of any gases that may be present)

- packaging groups I, II, III (density kg/l)

- shelf life from filling date (if applicable)

Approval numbers

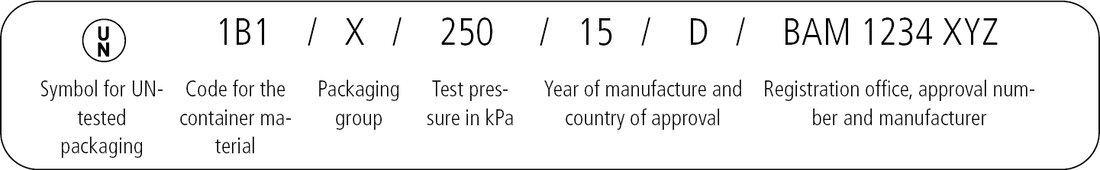

The identification contains the symbol for UN-tested packaging, the code for the container material, packaging group, test pressure in kPa, year of manufacture, country of approval, registration office, approval number and manufacturer.

If the approval number contains a letter (e.g. F or S) in the position that would otherwise be occupied by the test pressure in kPa then the packaging is only approved for use with solids, not with liquids.

New approval numbers apply for all types of transport, i.e. there is no longer any limitation to road, rail, sea or air transport.

Packaging containers with UN approval:

Wide-neck reagent bottles

UN bottles

HDPE jerrycan

Aluminium bottle

Transport bottle aluminium UN

Disposal kegs, wide-mouth containers

Wide-necked container for disposal or storage of powders, granulates and liquids. Can be closed tightly and sealed. The containers have an UN transport approval for solids.

Electrically conductive canister with UN approval

Safety jerrycans stainless steel with UN approval

Safety canister made of stainless steel AISI 316 Ti (1.4571).

Safety storage container stainless steel with UN approval

Safety containers for transport and storage with thickness of sides of 1.2 mm (25 l).

The 25 l container can be stacked.

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

português (Brasil)

português (Brasil)

Türkçe

Türkçe

中文

中文

한국어

한국어